Spx flow что это

Our Company

Our work is technical, our customer’s challenges are complex and we pride ourselves on finding innovative and sustainable solutions. We’re based in Charlotte, N.C., with operations in more than 30 nations and sales in more than 140 countries. Our landmark facilities are Innovation Centers, which are located around the globe. These state-of-the-art collaboration labs are where we partner with leading nutrition, health and industrial manufacturers, bringing together trusted brands and technologies to meet new consumer expectations and anticipate industry trends. The result: new standards of quality, consistency and cost-effectiveness, as well as safety and sustainability. We’ve been a standalone company since 2015, but our roots date back more than a century.

WHAT WE DO

We pioneered homogenizers, which explains how we help customers make products that meet the growing demand for enhanced nutritional and plant-based products. We partner with customers to extend the shelf life of milk, creams and processed cheese without losing nutritional value, flavor or appearance. From ketchup and yogurt to your favorite detergent and hand sanitizer, our pumps are the foundation of a processing system, ensuring the highest quality of product from creation to consumer. We also make mixers, valves, separators and heat exchangers to help produce customized solutions safely, sustainably and consistently.

Our Precision Solutions team’s work ranges from designing technologies for building bridges and stadiums to processing raw materials and chemical elements needed to make batteries for electric vehicles. During Covid-19, we worked around the clock to ensure our mixers and evaporators helped companies manufacture the vaccine at a record pace. We partner with a range of customers. Some are in the mining and marine industries, others are chemical and construction companies and some need to treat either water or air. Our industrial process solutions include compressed air dryers, mixers, pumps, hydraulic technologies and heat exchangers.

Spx flow что это

We’re proud to announce the opening of our latest Innovation Center in Dubai. This new facility provides the region with a UHT solution that stretches the value chain from research and development all the way to packaging.

Stories in the Making

From mining and chemical to dairy and plant-based solutions, discover what our global solution makers have been up to in our new blog.

Learn more about SPX FLOW

We create essential solutions for customers who, in turn, create food, medicine, clean water and other products we all need every day.

DT4 Tank Outlet Valve

Used for the reliable separation between a tank and a servicing pipeline, the DT4 tank outlet is an extension to the D4 Series mix proof family.

Seital Direct-Drive Centrifuge

Now offering direct-drive centrifuges on its most popular separators. In addition to requiring less energy, this makes for more space-efficient, quieter and easier-to-maintain units.

Ultra High Temperature

The core to effective UHT treatment is finding the balance between optimal temperature and processing time. Through careful product testing, a UHT process has the potential to extend product longevity and retain the quality taste, texture and depth of the original product.

Mixing & Blending

SPX FLOW application engineers develop customized mixing and blending solutions to the specific process needs of a customer.

Separation

The separation process includes the collection of eventually present solids and the de-watering of suspensions or bio-masses. The process of separation is often implemented to separate valuable liquids or solids from within a solution.

Power & Energy Brands

The former SPX FLOW Power & Energy business is now Celeros Flow Technology. Visit their dedicated website for ClydeUnion Pumps, MJ Valve, Copes-Vulcan or any of the other legacy SPX FLOW Power & Energy brands.

Food Processing

The food processing industry is year-by-year adapting to the modern demand of an ever-changing global market. With the emergence of generation Y and Z as decision-makers in the global food processing market, contemporary trends are playing a large role in customer buying decisions.

Chemical Processing

The chemical processing industry is essential to the production of mass consumer products and vital raw materials. SPX FLOW constructs holistic production lines and unit operations to build a competitively optimal chemical processing system. Utilizing the range from the SPX FLOW brand portfolio, SPX FLOW can research, develop and test customized chemical processing equipment optimized to the needs of the customer.

Pharmaceutical

SPX FLOW develops dedicated mixing, heat transfer, pneumatic, and dehydration systems for the pharmaceutical processing industry. Leveraging over a century of experience, a global network of research and development centers, and a dedicated staff of knowledgeably application engineers, to develop highly specialized pharmaceutical processes.

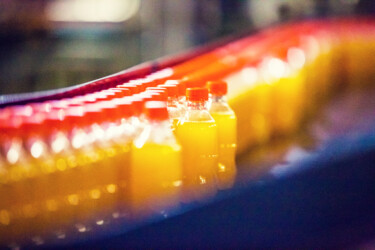

Beverage Processing

The beverage processing industry is, at its core, deeply variable because of the expansive range of product types. Meeting the industrial demand for fruit juices, alcoholic beverages, and health drinks, leads a multitude of nuances for each product type within the beverage processing industry.

Seital Separation (brand of SPX FLOW Technology)

Итальянский завод по производству сепаратор в Seital входит в группу компаний SPX FLOW (штаб-квартира в США).

Специализация завода — технологии сепарирования и осветления, основанные на 40-летнем опыте проектирования, производства и сборки оборудования.

Оборудование бренда Seital позволяет удалять взвешенные твёрдые частицы из жидкостей, разделять жидкости с различным удельным весом, извлекать полезные твёрдые частицы из жидких суспензий и обезвоживать суспензии для повышения уровней концентрации. Оборудование Seital применяется при обезжиривании молока, концентрировании сливок, осветлении пива, вина, а также обработке химикатов и био-растворов (например, осветление растворителями, концентрация биомассы). При производстве удобрений, технических жидкостей (например, очистке смазочных материалов). Фармацевтических продуктов (например, при производстве антибиотиков).

На заводе SEITAL производятся ключевые узлы сепараторов, включая барабан и пакет тарелок. Инновационный конструктив которых обеспечивает эффективность сепарации, качество и безопасность производственных процессов. Компоненты изготавливаются из особо прочных нержавеющих материалов в соответствии с международными производственными стандартами, а большинство изделий по своим характеристикам превышают законодательно установленные нормы.

Сlever Machines – официальный дистрибьютор и сервисный центр компании SPX FLOW Seital

О сотрудничестве

С основателями Clever Machines мы познакомились ещё 11 лет назад. Сергей и Анатолий тогда только создавали свою компанию. С самого начала меня приятно удивило тонкое техническое понимание дела с их стороны. Мы доверились им, как партнёрам, о чём ни разу не пожалели. Это был оправданный риск — они всегда отвечают за свои слова и исполняют обещания.

За последние годы наше сотрудничество с Clever Machines заметно выросло с технической точки зрения, но что никак не изменилось — мы по-прежнему остались друзьями и сохранили тёплые отношения. Рады за наших партнёров в «Клевере» — сейчас это сильная и профессиональная команда, в каждом участнике которой проглядываются своего рода «следы воспитания» Сергея и Анатолия.

Alberto Pielli, Руководитель отдела продаж сепараторов Seital в Европе и Африке, SPX FLOW Seital Separation Technology

Оставьте заявку на подбор оборудования и прайс-лист

Separation

Industrial separation equipment is primary to the clarification process and ultimately product quality. Clarification is defined as the separation of two liquids having different specific gravities. The separation process includes the collection of eventually present solids and the de-watering of suspensions or bio-masses. The process of separation is often implemented to separate valuable liquids or solids from within a solution.

Mechanical separation and clarification of liquids requires efficient and effective removal of suspended solids of various types and sizes combined with gentle treatment to preserve the quality of the end product. The most widely used method is centrifugation using a vertical disk stack – a technology that presents significant challenges in disk stack design in order to optimize separation with minimum product impact, while ensuring energy efficiency, operational reliability and a high level of safety.

Available in hermetic, hygienic, gas-tight, and explosion-proof designs in high-grade, corrosion-resistant stainless-steel materials, Seital separation brand series disk centrifuges ensure gentle and cost-efficient separation of liquids and suspended solids together with high reliability and safety.

SPX FLOW offers solids-retaining separators and clarifiers with hydraulic capacities from 132 to 2,642 g/h (500 to 10,000 l/h), and self-cleaning (solids-ejecting) separators and clarifiers with hydraulic capacities from 264 to 18,492 g/h (1,000 to 70,000 l/h). All feature Clean-In-Place (CIP) to ensure high sanitary levels with minimum downtime.

Seital brand series vertical disk stack centrifuges are fast and accurate, providing the assurance of reliable and repeatable performance with exceptionally high concentrations and clarities. Short CIP times increase productivity while ensuring the highest sanitary conditions. State-of-the-art design and an intuitive operator interface make Seital brand series centrifuges easy to regulate and adjust to ensure precise and repeatable product characteristics. By partnering with SPX FLOW, you can achieve improved performance efficiency, exceptional lifetime value in terms of initial investment, operational performance and ongoing service and reduced maintenance costs.

Juice

In juice separation, the capacity of the clarifier mainly depends on the separable solids content in the juice, the requested clarification degree and the maximum solids discharging capacity of the clarifier. The separable solids are evaluated by a lab centrifuge leading SPX FLOW application engineers to calibrate industrial separation solutions to the output specifics.

Wine

Wine is considered clarified when there are no longer visible suspended particles in the liquid, especially in more transparent wines. Wines may appear cloudy or dull if too much suspended matter remains, however a wine with suspended matter may have the same flavor and aroma as a fully clarified wine. To appeal to modern wine expectations, most wineries clarify wines before fermentation, to remove insoluble matter suspended in the wine. The clarification process includes a centrifugation period to quickly separate suspended matter without impacting the taste of the wine.

SPX FLOW designs clarifiers equipped with soft inlet feeding systems to minimize turbulence, product damage and oxygen pickup. Wines are often restricted from a high level of clarification due to the processes’ traditional level of product damage. SPX FLOW Seital brand series clarifiers offer high separation efficiencies due to their high centrifugal force and large separation capacities.

Dairy

Milk skimming is the separation of raw milk into skim milk and cream, both warm and cold milk skimming achieve this level of separation with differing processes. Skimming is a process that takes place after the clarification of the raw milk. The clarification of milk is often upon delivery to the dairy to remove dirt and somatic cell particles. The milk clarifier can operate with cold or warm milk. However, clarification efficiency improves at higher temperatures.

Warm milk skimming during pasteurization is the most common centrifugal separator application in dairies. The product temperature should normally be kept between 113°F and 131°F (45°C and 55°C ) in order to ensure optimal skimming efficiency. Skimming efficiency is influenced by a range of factors like the transport of the whole milk, milk storage temperature and time, seasonal variation, milk quality, mechanical treatment and free air-content upstream from the separator. Skimming efficiency is expressed as residual fat content in the skimmed milk.

Cold milk separation at 39.2 °F (4°C) takes place in several processes including cheesemaking and High-quality cream production. Cold milk separation enables significant savings in energy and thermal equipment such as heat exchangers. However, cold milk skimming efficiency is lower than that of warm milk skimming and cream concentration cannot exceed 40-42%. Skimming efficiency improves by increasing temperature and/or reducing flow-rate. Viscosity and other cream characteristics at low temperatures require the use of a special hermetic separator to achieve optimal skimming results.

Milk bacterial clarifiers are integral to improving the quality of drinking milk and cheese production. The general reduction of the number of bacteria and the important reduction in aerobic spores, anaerobic spores and listeria mean that pasteurization temperatures can be reduced. A reduction in processed temperature is often associated with better taste, texture and nutritional content. Milk bacteria clarification also helps avoid problems during cheese aging and improves shelf life and organoleptic properties of the milk. The milk bacteria clarification process can be performed in one of the following ways: continuous extraction of bacteria in the concentrated milk flow that must be sterilized before re-use; and extracted concentrate recycling in the feed and bacteria minimization by using only partial discharges. The first method results in minimum milk losses but requires a more complex and expensive treatment. The second method is the best compromise between installation costs, product quality and milk loss.

Cream

Cream concentration is a common task in the Dairy Industry. SPX FLOW separation technology offers specific units enabling the production of high-fat cream. By minimizing residual fat in the resulting buttermilk high-fat cream can be the first part of the processing for butter oil production or the starting point for alternative butter production.

Butter

When mechanical energy is applied to high-fat cream, phase inversion takes place. The cream from a stable milk fat emulsion becomes a mixture of oil and butter serum that can be processed in two stages in order to produce butter oil. The first step is to use an oil purifier to remove as much butter serum as possible from a 70-80% oil concentrate. An oil polisher is then used to produce butter oil ready for vacuum drying.

Brewing

SPX FLOW brand Seital designs hermetic separators to remove residual yeast and other non-soluble solids quickly and efficiently without impacting the flavor and aroma of the beer. Through extensive testing and numerous installations, SPX FLOW offers a wide range of experience and separation technology specifically designed for the needs of the beer processing industry. SPX FLOW designs for:

SPX FLOW specializes in supplying equipment that is configured to specific application requirements based on careful needs analysis together with our customers. Seital brand series separators and clarifiers are delivered on a compact, pre-assembled skid as “plug & produce” solutions. They are exceptionally efficient, compact and easy to fit into existing processing lines, thus enabling you to produce at full capacity immediately after connecting to power and water utilities. We also offer a wide range of separation process accessories enabling you to meet your separation and clarification needs from a single supplier.

SPX FLOW separation technology provides rapid troubleshooting assistance through the integration of remote monitoring. By connecting separation equipment to the SPX FLOW remote monitoring system, separation technicians have direct access to the machines specifics. Allowing SPX FLOW separation technicians can troubleshoot and rectify problems quickly, minimizing unscheduled factory downtime and production loss.

SPX FLOW employs a detailed manufacturing and inspection plan for critical manufacturing phases, using a specific dynamic rotor balancing procedure. Testing includes 3D measurement, dye penetrant, ultrasonics and hydraulic test as well as destructive testing, X-ray and metallographic tests. Component stress and strain analysis is performed using advanced Finite Elements Method Analysis software while efficiency testing is conducted using CFD (Computational Fluid Dynamics).

All SPX FLOW vertical disk stack centrifuges are designed and manufactured according to the CE Directive on machinery 2006/42/CE and its amendments. Main materials and components are sourced from certified ISO 9001 suppliers.

Other specific standards are:

SPX FLOW supports customers over the entire lifetime of their machines to help them maximize the value of their equipment in terms of performance and running time by making sure that service and maintenance take place according to plan. Customers can call on the support of our technicians wherever and whenever necessary, either for service and maintenance or for training of their own staff.

SPX FLOW assembles and delivers special spare parts kits to cover the lifetime of every machine. Our technicians advise our customers on which spare parts they should have at hand locally for scheduled service and maintenance.

The SPX FLOW Innovation Centers leverage the extensive industry expertise of technologists, process engineers and production engineers together. With knowledge accrued through actively contributing to the development, testing and application of SPX FLOW processing lines; the SPX FLOW innovation centers are staffed by experienced engineers. All facilities and services are designed to provide added value by minimizing waste, energy requirements or by converting commodity ingredients into new, competitive products.

Like other SPX FLOW brands, Seital maintains a robust research and development program for new product development, working closely with customers to understand and address the challenges they face. SPX FLOW combines its vast experience in the food, beverage, fats and oils, chemical, biotec and pharmaceutical industries with in-depth understanding of separation and clarification process requirements to deliver clear customer benefits in performance and total cost of ownership.

We provide pilot plant equipment for our customers to perform tests on site or in an SPX FLOW laboratory in order to evaluate separation performance for their process. Experienced SPX FLOW technicians provide full support with fast and efficient customization of separation and clarification machines to meet individual process and site requirements.

Our R&D seeks to meet three typical needs:

SPX FLOW innovation centers provide:

Innovation Centers

SPX FLOW Innovation Centers provide a state-of-the-art, collaborative space for customers to test, develop and perfect their critical manufacturing processes. These test facilities are intelligently designed to minimize waste, cost and development time in the product refinement process. SPX FLOW’s five Innovation Centers based in Dubai, UAE; Shanghai, China; Copenhagen, Denmark; Silkeborg, Denmark and Mamirolle, France, each host their own set of capabilities.

However, the SPX FLOW Innovation Centers work specifically to mitigate the daunting time, opportunity and financial cost of developing a product. Our innovation centers employ cutting-edge production technologies and the deep expertise of process engineers. The innovation center s ’ staffs are well-versed technologists, who have all accrued experience across several industries. The team at SPX FLOW will help develop a system that exactly fits any production needs. From designing the perfect texture and mouthfeel in the dairy industry to optimizing pharmaceutical production lines, SPX FLOW process engineers are dedicated to building efficient process solutions.

The SPX FLOW Innovation Centers are the optimal environment for scaled process testing, hosting a wide range of scalable test equipment and a number of magnified analysis systems to support internal and external trials. This test environment is therefore perfectly suited for high-risk projects, allowing an externally “safe” environment to troubleshoot applications and products. Yet the SPX FLOW Innovation Centers are more than safely removed test environments; they each offer a set of additional services and uses. Each manufacturing test environment offers product line optimization to reach the maximum yield and standard of quality, applied training courses, scale-up plans and full test center rentals.

The SPX FLOW Innovation Centers are pointedly focused on assisting in developing the innovative products and processes for the dairy, food and beverage, chemical and pharmaceutical industries.

The SPX FLOW Innovation Center in Dubai, UAE is the first research and development facility of its kind serving the Middle East and Africa. In collaboration with SIG Combibloc, our Dubai Innovation Center offers customers in the region a complete delivery solution that stretches the value chain all the way from research and development to packaging. Our newest center not only accelerates the time to market, but also virtually eliminates the cold chain. Plus, with the range of UHT processes available from dairy to plant-based, consumers in the MEA can stay ahead of consumer trends without leaving the region.

Facility Capabilities and Specialties

The SPX FLOW Innovation Center in Copenhagen, Denmark features a full range of drying, evaporation and crystallization technology systems. SPX FLOW process engineers assist customers in developing optimum output and factory performance, regardless of drying method. The innovation center staff are all well versed in a multitude of drying requirements, preserving proteins, waste steam recovery and working with dyestuffs. The innovation center houses spray drying, spin flash drying, aseptic drying and atmosphere drying systems; all available for trial.

The SPX FLOW Shanghai Innovation Center is positioned within a full-scale manufacturing campus operating production, research and development, engineering and distribution channels collectively. Functionally the SPXFLOW Shanghai Innovation Center offers cutting edge dairy manufacturing equipment developed by award-winning SPX FLOW brands. Process engineers of the SPXFLOW Shanghai Innovation Center are focused on creating optimized process solutions that meet food and beverage regulations and standards across the globe.

Facility Capabilities and Specialties

This facility focuses on providing a responsive test environment for the food and beverage industry. Designing, developing and optimizing food and beverage production processes requires a broad range of contemporary manufacturing equipment. The Silkeborg SPX FLOW Innovation Center was implicitly designed to provide customers with the exact tools to optimize their product and process.

The Silkeborg, Denmark SPX FLOW Innovation Center offers complete sets of scalable test equipment for dairy, food, and beverage industries. The Innovation Center’s laboratory is also deeply connected to a set of process-wide controls. This integrated system allows for detailed process analysis and product trials.

Facility Capabilities and Specialties

To support the development of fresh dairy products, the SPX FLOW Innovation Center located within the French National Dairy School (ENIL) features a range of modern dairy production equipment. This university, with experience in cheese making and other fermented products for more than 130 years, is comprised of two independent SPX FLOW pilot plants, specializing in the production development of fresh fermented dairy products like yogurts (set, stirred, drinking, flavored, Greek, high protein etc) and cheeses without whey separation (soft cheese, semi-hard cheese, spreadable cheese) using SPX FLOW patented technology respectively. Products can start from dairy or vegetable/plant-based ingredients. In addition to the range of developmental options, the campus is privy to the expertise of ENIL to assist customers in optimizing products, developing competitive product lines and construct ing long-term growth strategies.

Facility Capabilities and Specialties

SPX FLOW has put in place secure, remote procedures to procure raw materials and conduct trials on behalf of its customers, sharing results and shipping samples of products to customer sites on completion of tests. This means that even with the current travel restrictions, producers can continue to innovate and gain competitive edge with new product introductions and improvement programs.